商铺名称:广东益联电子科技有限公司

联系人:钟小姐(小姐)

联系手机:

固定电话:

企业邮箱:3048134259@qq.com

联系地址:广东省中山市东升镇胜利村祥胜路一巷28号

邮编:

联系我时,请说是在地方电气网上看到的,谢谢!

-

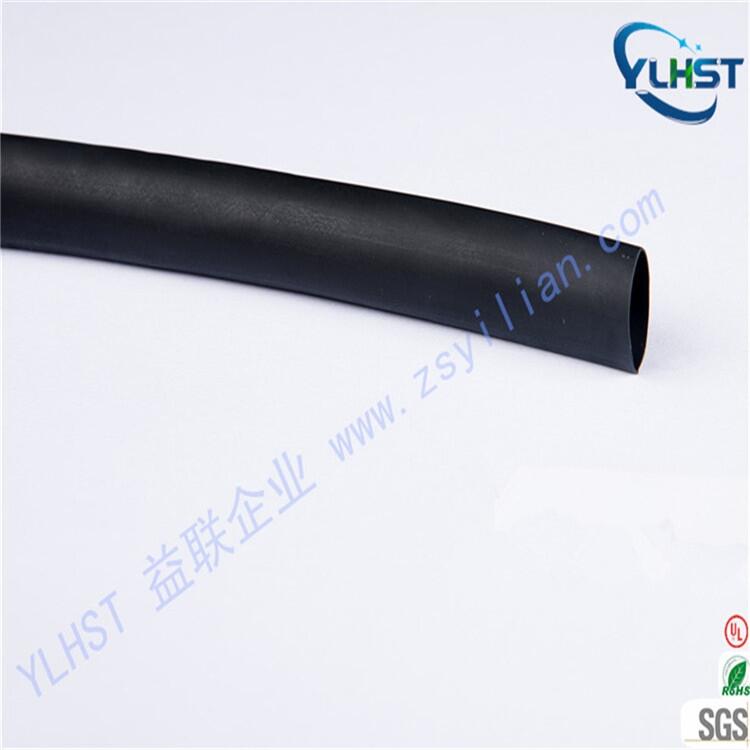

收缩比:2:1

-

柔软、弹性好、握感好

-

耐温等级高,达150℃,也可在180-200℃下短期或间歇使用

-

优异的电气绝缘性、耐候性、抗紫外光老化性能

-

优异的耐酸碱和化学溶剂性能

-

符合ROHS、REACH等环保规范

颜色

-

标准颜色:黑色

-

其他颜色可定制

操作温度范围

-

连续使用温度范围:-55℃~150℃

-

最低起始收缩温度:70℃

-

最低完全收缩温度:120℃

符合标准

-

SAE AMS-DTL-23053/13

性能指标

-

Shrink ratio: 2:1

-

Flexible, elastomeric.

-

150℃ temperature rating, also shortly used at 180-200℃.

-

Excellent insulation, weather resistance and UV resistance.

-

Excellent resistance to acid, base and chemical solvent.

-

ROHS and REACH compliant.

Color

-

Standard color: Black

-

Other color are available on request.

Operating Temperature Range

-

Operating temperature: -55℃~150℃

-

Minimum shrink temperature: 70℃

-

Minimum fully recovery temperature: 120℃

Approvals

-

SAE AMS-DTL-23053/13

Property

EP150 EPDM热收缩套管

应用

由三元已丙橡胶(EPDM)经特殊工艺加工而成,与普通三元已丙橡胶管相比,该产品的物理机械性能更好,耐电压等级更高、耐磨性虚好。主要应用于线缆线束或电子元件的绝缘保护,焊点防绣防腐、机械防护和防水密封等,广泛应用于电子、汽车、装饰和灯饰工程和消费品等。

特性

|

性能 |

指标要求 |

测试方法 |

典型值 |

|

纵向收缩率 |

≤10% |

ASTM D 2671 |

≤5% |

|

抗张强度 |

10.4MPa min |

ASTM D 638 |

≥12MPa |

|

断裂伸长率 |

200% min |

ASTM D 638 |

≥400% |

|

老化后抗张强度 (热老化180℃,168小时) |

7.3MPa min |

ASTM D 638 |

≥9.8MPa |

|

老化后断裂伸长率(180℃,168hrs) |

100% min |

ASTM D 638 |

≥200% |

|

低温柔软性 (-55℃,4小时) |

无裂痕 |

ASTM D 2671 |

无裂痕 |

|

绝缘耐压和击穿 |

2000V,60sec,不击穿 |

ASTM D 2671 |

通过 |

|

击穿强度 |

10 KV/mm min |

ASTM D 2671 |

≥12KV/mm |

|

体积电阻率 |

1013??cm min |

ASTM D 876 |

≥1013??cm |

规格尺寸

|

规格 |

收缩前(mm) |

收缩后(mm) |

适用范围 (mm) |

标准包装 (m/卷) |

|

|

内径(min) |

内径(max) |

壁厚 |

|||

|

Ф6 |

6.0 |

3.0 |

0.80+0.10 |

3.5-6.0 |

50 |

|

Ф8 |

8.0 |

4.0 |

0.90+0.10 |

4.5-8.0 |

50 |

|

Ф12 |

10.0 |

5.0 |

1.20+0.10 |

5.5-9.5 |

50 |

|

Ф14 |

12.0 |

6.0 |

1.20+0.10 |

6.5-11.5 |

50 |

|

Ф16 |

16.0 |

8.0 |

1.50+0.15 |

8-15 |

30 |

|

Ф20 |

20.0 |

10.0 |

1.50+0.15 |

11-19 |

30 |

|

Ф30 |

30.0 |

15.0 |

1.80+0.15 |

17-29 |

20 |

|

Ф40 |

40.0 |

20.0 |

2.00+0.20 |

22-38 |

20 |

|

Ф45 |

45.0 |

22.0 |

2.00+0.20 |

25-43 |

20 |

|

Ф50 |

50.0 |

25.0 |

2.00+0.20 |

27-48 |

20 |

|

Ф60 |

60.0 |

30.0 |

2.10+0.30 |

32-58 |

10 |

|

Ф70 |

70.0 |

35.0 |

2.10+0.30 |

37-68 |

10 |

其他规格尺寸可定制

EP150 EPDM Heat Shrinkable Tubing

Application

It is specially manufactured by EPDM compound. Compared to normal EPDM tube, it has better physical properties, higher voltage rating and better abrasion resistance. It is mainly applied for insulation protection of cable harness and connectors, anti-corrosion and water-proof of welding spots in electronic, automotive, decoration and consumption fields.

Characteristics

|

Property |

Requirement |

Test method |

Typical data |

|

Longitudinal shrinkage |

≤10% |

ASTM D 2671 |

≤5% |

|

Tensile strength |

10.4MPa min |

ASTM D 638 |

≥12MPa |

|

Elongation at break |

200% min |

ASTM D 638 |

≥400% |

|

Tensile strength after aging (180℃,168hrs) |

7.3MPa min |

ASTM D 638 |

≥9.8MPa |

|

Elongation after aging (180℃,168hrs) |

100% min |

ASTM D 638 |

≥200% |

|

Low-temperature flexibility(-55℃,4hrs) |

No crack |

ASTM D 2671 |

No crack |

|

Dielectric voltage withstand |

2000V,60sec,no breakdown |

ASTM D 2671 |

Pass |

|

Dielectric strength |

10 KV/mm min |

ASTM D 2671 |

≥12KV/mm |

|

Volume resistivity |

1013??cm min |

ASTM D 876 |

≥1013??cm |

Sizes

|

Size |

As supplied(mm) |

After recovered(mm) |

Application range (mm) |

Standard packing (m/roll) |

|

|

Inside diameter(min) |

Inside diameter(max) |

Wall thickness |

|||

|

Ф6 |

6.0 |

3.0 |

0.80+0.10 |

3.5-6.0 |

50 |

|

Ф8 |

8.0 |

4.0 |

0.90+0.10 |

4.5-8.0 |

50 |

|

Ф12 |

10.0 |

5.0 |

1.20+0.10 |

5.5-9.5 |

50 |

|

Ф14 |

12.0 |

6.0 |

1.20+0.10 |

6.5-11.5 |

50 |

|

Ф16 |

16.0 |

8.0 |

1.50+0.15 |

8-15 |

30 |

|

Ф20 |

20.0 |

10.0 |

1.50+0.15 |

11-19 |

30 |

|

Ф30 |

30.0 |

15.0 |

1.80+0.15 |

17-29 |

20 |

|

Ф40 |

40.0 |

20.0 |

2.00+0.20 |

22-38 |

20 |

|

Ф45 |

45.0 |

22.0 |

2.00+0.20 |

25-43 |

20 |

|

Ф50 |

50.0 |

25.0 |

2.00+0.20 |

27-48 |

20 |

|

Ф60 |

60.0 |

30.0 |

2.10+0.30 |

32-58 |

10 |

|

Ф70 |

70.0 |

35.0 |

2.10+0.30 |

37-68 |

10 |

Other sizes are available upon request.